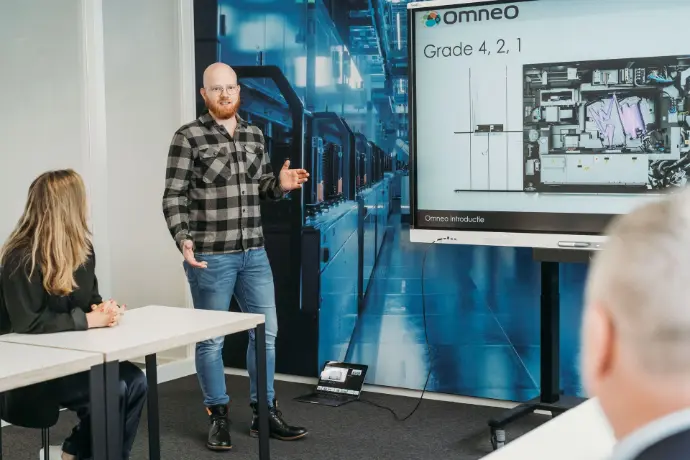

Training &

Consultancy

Training at Omneo; insight,

control,

and perfection in process cleanliness

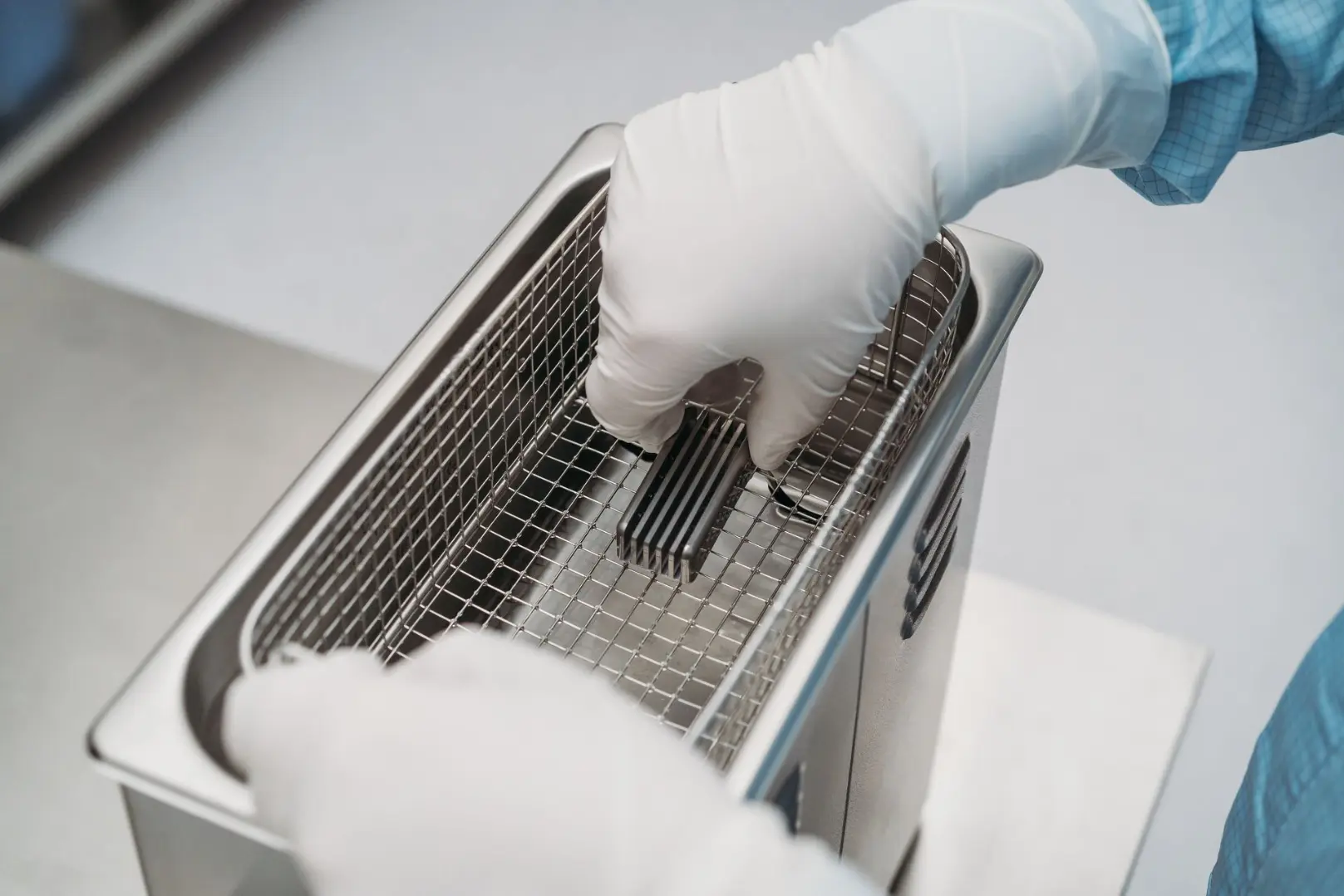

For anyone working in or near a cleanroom, understanding process control is essential. The level of cleanliness directly determines product quality and reliability. Through Omneo’s training programs, participants learn how contamination arises, how it is measured, and most importantly how to design processes that prevent it from occurring.

Core Program;

One-day Process

Cleanliness Training

Omneo offers a specialized one-day training designed for professionals in the high-tech and semiconductor production chain. The program is suitable for developers, operators, engineers, supervisors,?, ?, and quality professionals who want to deepen their understanding of cleanliness and process control. Each session is tailored to the participants’ knowledge level and specific interests for maximum relevance and impact.

Modules

What is clean and why does it matter?

How is cleanliness measured?

How is clean production achieved?

How is cleaning performed?

How is cleanliness maintained?

Advanced topics RGA and mass spectrometry

Location & facilities

Trainings are preferably held at Omneo’s facility in Best, featuring:

- A fully equipped laboratory

- A certified cleanroom

- Specialized instruments, including multiple Residual

- Gas Analysers (RGA)

- Optional Particle Deposition Monitor

- (PDM) demonstrations

- Onsite training at the customer’s location is possible upon request (additional travel and accommodation costs apply).

Included:

- A full-day training for up to 8 participants

- Access to equipment and facilities

- Lunch, coffee, tea, and soft drinks (when held in Best)

Beyond this one-day core training, Omneo also offers extended programs for professionals seeking deeper expertise, including the Cleanbelt Basic, Cleanbelt Full, and Cleanbelt Expert courses.Contact us to discuss which program best fits your organization or team.

Consultancy

Expertise that makes

processes predictable and controllable.

Omneo supports organizations

in the high-tech industry by analyzing, optimizing, and validating production

processes. With in-depth knowledge of cleanliness, process control, and

contamination management, we help companies gain control over every step in

their chain.

From assessing materials and cleaning methods to validating

complete production lines, our consultants combine technical precision with

practical implementation. We operate independently, transparently, and with an

eye for detail. This ensures that processes not only meet industry standards

but also perform consistently, sustainably, and reliably.